AR Series - AC Input  Built-in Controller Type

Built-in Controller Type

Adopting Oriental Motor’s Original Closed Loop Control:

The AR Series uses our closed loop control to maintain positioning operation even during abrupt load fluctuations and accelerations. The rotor position detection sensor monitors the rotation. When an overload condition is detected, the AR Series will instantaneously regain control using the closed loop mode.

For details, refer to "Overview of Stepping Motor and Driver Packages αSTEP"

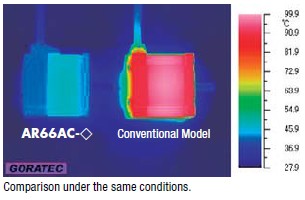

Continuous Operation is Achieved Due to the Reduction of Motor Heat Generation by Utilizing High-Effi ciency Technology:

- Lower Heat Generation

The AR Series utilizes high-efficiency technology to achieve a significant reduction in the amount of heat generated from the motor.

●Temperature Distribution by Thermography

●Motor Case Temperature under Same Operating Conditions

- Energy-Saving

Power consumption: up to 66% less✽ than a conventional model

●Power Consumption

Flex Types of Operation Systems:

Stepping motor and driver packages combine a stepping motor selected from various types with a dedicated driver. In addition to the pulse input type, drivers with a built-in controller type is also available.

Combination products

Built-In Controller Package:

The burden on the programmable PLC is reduced because the information necessary for motor operations is built into the driver. This simplifies the system configuration for multi-axis control. Set with control module (sold separat ely), data setting software, or RS-485 communication.

ely), data setting software, or RS-485 communication.

Operation type:

With built-in controller packages, the motor’s operating speed and traveling amount are set with operating data and operations performed based on the selected operating data. The operation type is 4-pattern.

Positioning Operation

Return-To-Home Operation

Continuous Operation / Other Operations

Group Sending Function

(Via RS-485 communication or Network Converter)

Groups can be configured with multiple axes connected via RS-485 communication, and commands sent for each group. Multiaxis simultaneous starting and identical operations are also possible.

Teaching Function:

Teaching can be done using the control module OPX-2A (sold separately) or data setting software MEXE02✽. The table is moved to the desired position, and the position data at that time stored as the positioning data.

※Data setting software also distributes a CD-ROM.

| Types | Frame Size [mm] | Resolution Setting: 1000 P/R [˚/Pulse] | Maximum Holding Torque [N・m] |

|---|---|---|---|

| Standard Type | 42 | 0.36 | 0.3 |

| 60 | 1.2 to 2 | ||

| 85 | 2 to 4 | ||

| TH Geared Type | 42 | 0.012 to 0.1 | 0.35 to 1.5 |

| 60 | 1.25 to 4 | ||

| 90 | 4.5 to 12 | ||

| FC Geared Type | 42 | 0.012 to 0.05 | 0.7 to 3 |

| 60 | 2.5 to 10.5 | ||

| PS Geared Type | 42 | 0.0072 to 0.072 | 1 to 3 |

| 60 | 3.5 to 8 | ||

| 90 | 10 to 37 | ||

| PN Geared Type | 42 | 0.036 to 0.072 | 1.35 to 1.5 |

| 60 | 0.0072 to 0.072 | 3.5 to 8 | |

| 90 | 10 to 37 | ||

| Harmonic Geared Type | 42 | 0.0036 to 0.0072 | 3.5 to 5 |

| 60 | 5.5 to 8 | ||

| 90 | 25 to 37 |

Built-in Controller Type

Built-in Controller Type